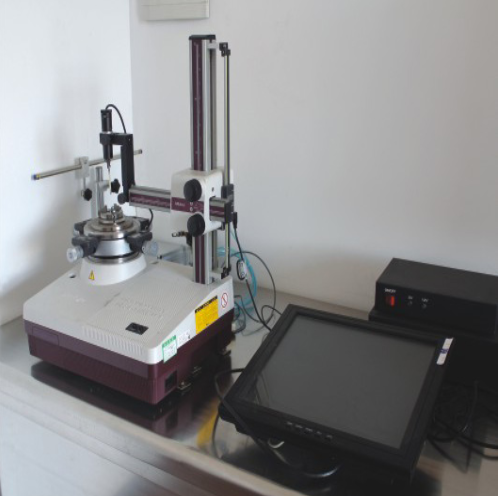

Shenyang Jiaxin Steel Ball Factory boasts a large-scale production and processing equipment, with more than thirty sets of grinding ball equipment and over forty sets of grinding ball equipment. It is equipped with several (sets) of imported high-speed cold heading equipment and heat treatment production lines valued at over one million yuan, leading the industry in production equipment. At the same time, the company has the most advanced eddy current flaw detection equipment in the domestic industry, mainly used to detect internal structural defects of finished steel balls.

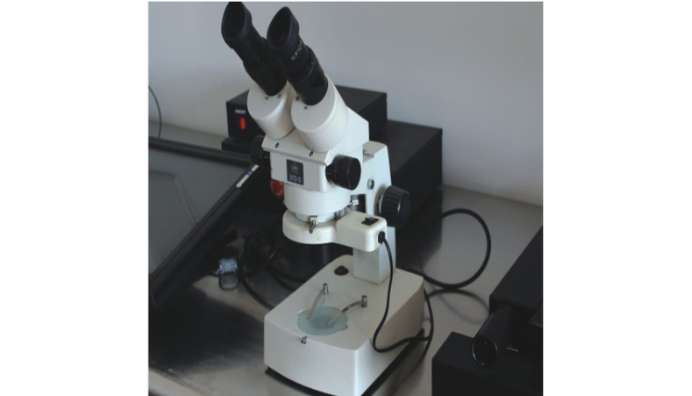

Over the years, the company has continuously introduced the world's leading AVIKO-2 type eddy current photoelectric flaw detector, capable of flaw detection for large-sized bearing steel balls above 50.80mm, effectively reducing the possibility of internal structural defects in large-sized bearing steel balls. In addition, the company is equipped with multiple (sets) of appearance photoelectric detection equipment for surface inspection of ball blanks, ensuring that the surface of the ball is free from scratches, rust, and other defects, thereby extending the service life of the steel balls.